Key sectors

Combined Heat and Power

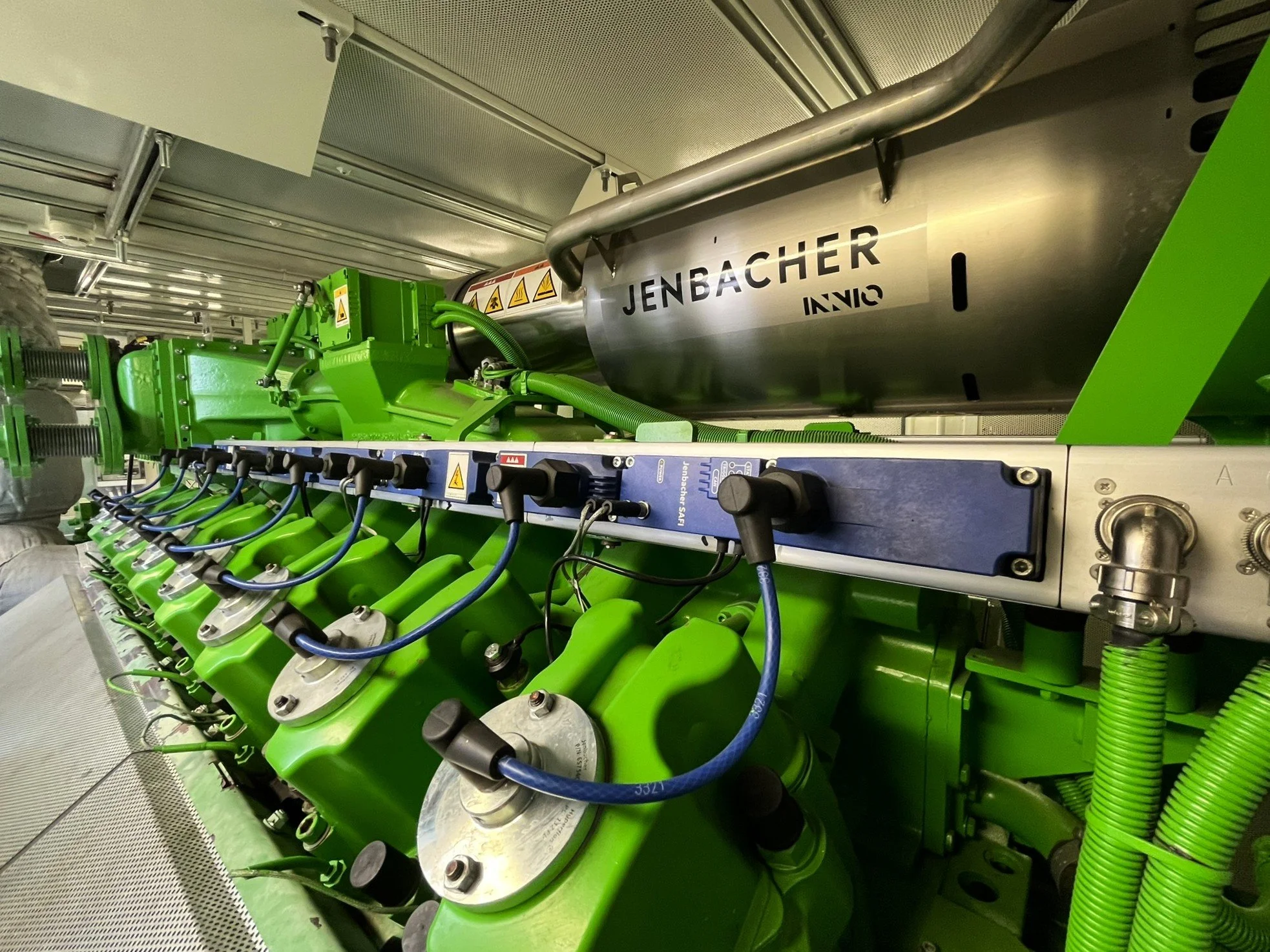

Combined Heat and Power (CHP) units are one of the most efficient ways of using a fuel to generate electricity. This is because, instead of throwing away the heat that is 'left over' as large power stations do, the heat is put to good use.

We work with businesses that own and operate CHP on sites such as commerical greenhouses and even hospitals. We also work with operators of district heating networks in towns and cities and Energy Services Companies that invest in CHP and then sell the heat and electricity to the host site.

We cover topics such as:

Re-billing heat and electricity to the end user

CHPQA accreditation and annual returns, quarterly CCL returns, MCPD permitting and compliance

Daily run regime changes using automated systems linked to the day-ahead electricity markets

Assessing the benefits of grid support services such as Capacity Market, Short Term Operating Reserve etc.

Key to all of this is developing a deep understanding of the energy demand dynamics of a site and whole of life CHP operating costs.

Greenhouses

We have worked with many of the best commercial greenhouse businesses in the UK from salads crops and soft fruit to flowers and more novel crops. Tim and Ben have also been a regular speaker at industry events like the British Tomato Growers Association annual conference.

Energy can be as much as 40% of the annual operating cost of some commercial greenhouses, so it is no surprise that energy use and cost is always high on their agenda. This has driven levels of energy management and technology that are often far ahead of many other industries.

A typical package includes:

Invoice validation and issue resolution

Medium Combustion Plant Directive permit facilitation

…even remote monitoring of greenhouse control systems and system optimisation / troubleshooting.

Whether you already have a commercial greenhouse, are planning on building one or want to supply energy to one we can help.

Anaerobic Digestion

Members of our team and extended network have been providing support to Anaerobic Digestion (AD) plants for over ten years, typically including:

Energy contract tenders and ongoing management - fixed price or flexible trading

Feed-in Tariff compliance

REGO compliance and management

Arranging and running energy billing for private wire supply

With many generators’ FiT and RHI subsidies heading towards their end, we’re heading into an interesting time for AD plants. Our industry connections and foresight will ensure that we’re perfectly placed to make the most of opportunities and run profitably well beyond the end of subsidies.

Farming

Farming is in Tim’s genes, and whilst modern farming has changed massively since he last drove a tractor in anger it is rare that a day goes by without farming being mentioned in conversation with friends, family or clients. This helps us to understand the sometimes unique energy requirements of farms and the different approach to investments by what is often a family business.

The electricity demand on farms varies from not much more than a house and office or workshop to a site storing and processing thousands of tonnes of produce or rearing thousands of animals every year; there is rarely a one size fits all solution. As is the case for everything that we do, it is important to take time to understand the energy needs of the business and their approach to cost management and investment to ensure the best solution and service is provided.

Food industry

The food industry uses a lot of energy for quite varied applications depending on the particular product. It can be:

Refrigeration for storage and packing areas

Heat for drying, pasteurising, cooking and cleaning

Lighting in packing and inspection areas

Packing lines, compressed air, office and staff facilities

Effluent treatment.

Many such facilities often operate seven days per week and even 24/7; they rarely run a standard 40 hour working week. With refrigeration being common, unlike many businesses the highest electricity use tends to be in summer rather than winter.

Bespoke fixed price electricity supply contracts and even flexible contracts can give the best outcome for food industry businesses. If natural gas is available, high year-round electricity demand combined with a need for heat has driven increased interest in CHP in recent years.

Heat networks

Heat networks are seen as a key means of providing low carbon heat in urban areas in particular. They facilitate the installation of low carbon heat sources such as Combined Heat and Power (CHP) and heat pumps which benefit from economies of scale and cannot always be installed at the point of heat use.

Due to the high capital cost, heat networks are often owned and managed by large companies, local authorities etc. The heat customer is billed for each kWh of heat used. A key point is that the heat customer cannot ‘shop around’ as they do for gas or electricity so the price paid per kWh of heat is often linked to the price of the ‘normal’ heat source such as gas.

We work at the front end of heat production rather than the consumer metering and billing end. Our experience with CHP for greenhouses naturally extends into running CHP for heat networks:

Operating cost analysis